Zünd

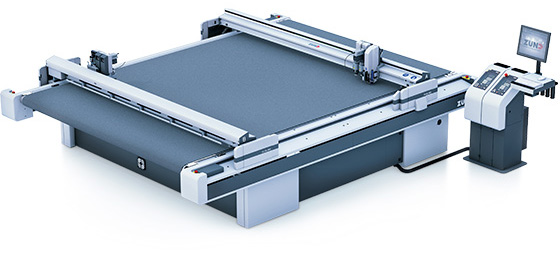

D3 Cutter

Double your productivity

- Maximum throughput and performance

- Large-format production

- Efficient dual-beam workflow

Mind Technology

Creative Solutions for Your Industry

Mind Technology

Creative Solutions for Your Industry

With its dual-beam system, the Zünd D3 delivers the ultimate in productivity. Because of its powerful, rugged design, the D3 lives up to its true potential in industrial environments.

The D3 Cutter is a precision machine. From innovative drive system to blade, all components are perfectly coordinated. Produce your jobs at the highest quality level, economically and efficiently. Your customers will be thrilled with the results.

The extraordinary modularity of our cutting solutions is truly unique. You can always make your D3 cutting system adapt to new requirements with modifications and upgrades. Zünd cutters are a safe investment and offer maximum value retention. Zünd's modular design concept lets you put together a tailor-made cutting solution configured to meet specific production needs.

The price-performance ratio of the D3 cutter series is excellent. We use only the most modern technologies and highest-quality components. The flexibility, reliability, and quality of the D3 cutter cannot be matched by any competitor.

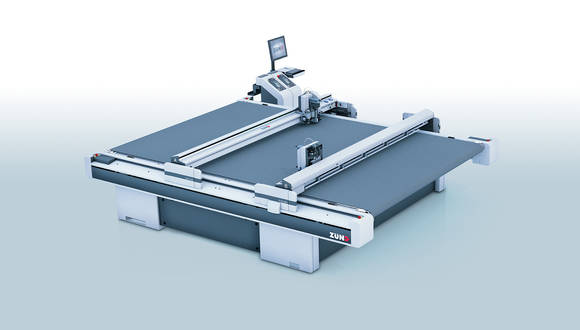

The D3 has two beams that operate independently. Depending on the job, this can double your productivity. The intelligent cutter controller allocates the work optimally to each of the two beams.

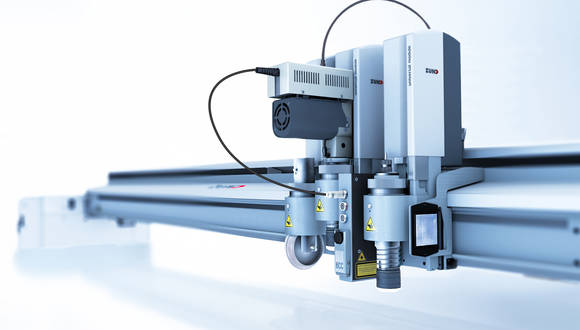

You have the flexibility to choose precisely the tools you need for the job at hand. Combine the required tools based on your specific requirements. You can equip the D3 with up to three different tools per beam.

The setup of of knife-cutting, routing, and creasing tools occurs fully automatically. The ITI Initialization System makes the process quick and precise.

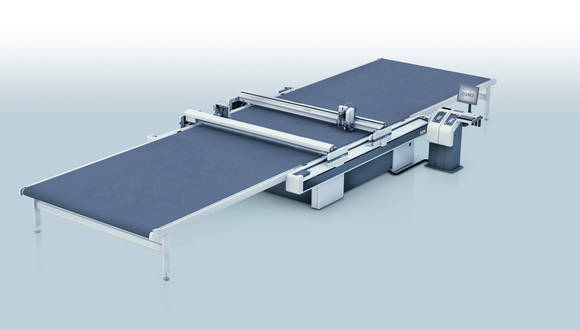

Configure the D3 according to your specific needs, with cutter extensions and/or material-handling solutions. Just like the cutter, all these options were designed with an eye towards ergonomics. The cutter is easily accessible from all sides, which ensures an efficient production workflow.

Width (in mm/in)

1800 / 70

Length (in mm/in)

3200 / 126

Width (in mm/in)

2270 / 89

Length (in mm/in)

3200 / 126

Width (in mm/in)

2740 / 107

Length (in mm/in)

3200 / 126

Width (in mm/in)

3210 / 126

Length (in mm/in)

3200 / 126